Stainless Steel

tainless steel alloys have excellent mechanical properties, including high tensile strength, ductility, wear resistance, and corrosion resistance even at high temperatures.

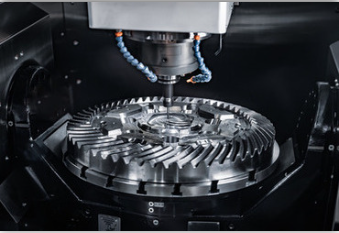

Expert CNC Stainless Steel Machining Service

PY-Precision is your top choice for dependable and efficient stainless steel components. Our ISO 9001-certified facility offers cutting-edge precision on custom designs with options ranging from rapid prototyping up to high-volume production of parts ready for use. We make sure you enjoy quick turnarounds in a trustworthy environment without fail!

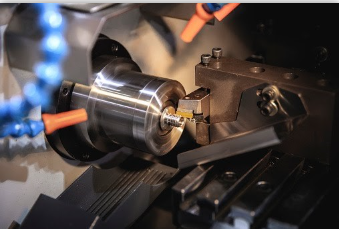

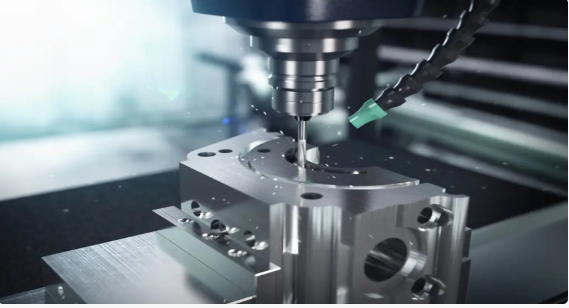

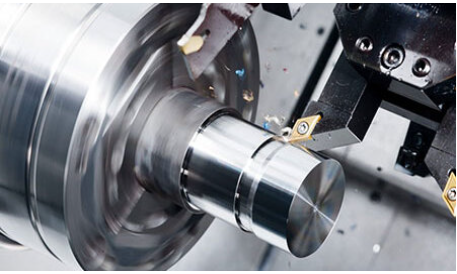

Our specialized team provides unparalleled CNC machining services, including milling, turning, and lathe work. Prices are tailored based on the product’s stage of development so that you benefit by getting the highest value at an unbeatably fast delivery timeframe every time! The dedicated experts we have on staff always stand ready to provide bespoke support when needed – helping ensure success in achieving all project goals.

About The Material

Stainless steel is an ideal material for CNC machining due to its excellent workability and amazing uniformity. Its impressive ability to resist corrosion, wear and tear. High tensile strength makes it a top choice amongst industrial settings seeking superior quality components that stand the test of time. The metal also offers great ductility and formability to meet specific project parameters with ease – all making stainless steel one of the most sought-after materials for precision machinery such as CNCs.

Corrosion resistance

Strength

Versatility

Surface

Durability

Stainless Steel Alloys For CNC Machining

Stainless steel CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut stainless steel into precise and complex parts or products.

During the CNC machining process, a computer program is used to control the movement and operation of the cutting tools, which allows for highly accurate and repeatable cuts. This results in parts with tight tolerances and complex geometries, which are difficult or impossible to achieve using traditional machining methods.

With a wide selection of stainless steel variations, we have everything you need to complete your CNC machining project with precision and excellence. From Stainless Steel 304/304L and 316/316L to 303 or Type 360 (17-4) etc, our options are guaranteed to deliver the highest quality performance that meets any specifications or requirements you may have!

Including but not limited to the following materials

Stainless Steel 303

Easy to machine, good corrosion resistance, not suitable for welding, ideal for nuts, bolts.

Stainless Steel 304/304L

Corrosion resistant, good formability, widely used in kitchens, tubing, and outdoors.

Stainless Steel 316/316L

Higher corrosion resistance than 304, marine grade, used in harsh chemical environments, surgical instruments.

Stainless Steel 416

High machinability, lower corrosion resistance, magnetic, commonly used for gears, valves, and pump shafts.

Comparison Of Common Stainless Steel Alloys

Learn the characteristics of various grades of stainless steel and choose the right material for your project

| SS303 | SS304 | SS304L | SS316 | SS316L | SS17-4 | SS410 | SS416 | SS420 | |

| Hardness, Vickers | 167 | 129 | 159 | 199 | 199 | 349 | 446 | 383 | 641 |

| Tensile Strength, Ultimate | 690 Mpa | 505 MPa | 564 Mpa | 620 MPa | 585 Mpa | 1103 Mpa | 1525 MPa | 515 Mpa | 1600Mpa |

| Tensile Strength, Yield | 415 Mpa | 215 MPa | 210 Mpa | 415 MPa | 380 Mpa | 1000 Mpa | 1225 Mpa | 275 Mpa | 1360Mpa |

| Elongation at Break | 40% | 70% | 58 % | 45 % | 45 % | 15% | 14.5% | 30% | 12% |

| Modulus of Elasticity | 193 GPa | 193-200 Gpa | 193 - 200 Gpa | 193 GPa | 193 GPa | 197 Gpa | 200 Gpa | 200 Gpa | 200 Gpa |

Characteristics Of CNC Machining Of Stainless

Stainless steel material is more difficult to process than steel, not only considering the processing problems but also the performance of different types of stainless steel to choose the corresponding processing technology. The machining quality and efficiency can be guaranteed by a reasonable selection of tool materials, geometric parameters, and cutting parameters

Stainless steel in the cutting process, severe hardening, plastic deformation, high thermal strength, and cutting force. And poor thermal conductivity, the heat taken away by the chip is very little, and cutting heat is mainly concentrated in the tool near the edge, resulting in rapid tool wear.

Under the same conditions, stainless steel and other metals with strong affinity, easy to make the tip of the chip tumor and after the tool surface to produce adhesion, resulting in rapid tool wear. And because the frequent sharpening, and tool replacement, affects productivity.

In the cutting process, the machined surface is easy to form a hardened layer. As the stainless steel plasticity and toughness are relatively large, the chip is not easy to break, both affect the smooth operation, the processed surface damage is also large, so it is not easy to obtain a lower value of surface roughness.

The difference between milling and turning is that milling is intermittent cutting, the cutting process of each tooth depth of cut changes all the time, easy to produce vibration and impact, so the cutting conditions are worse than turning. In reverse milling, the tool teeth first in the hardened surface glide, increasing the tendency of hardening; milling impact and vibration so that the tool teeth are easy to chip and wear.

So should be used as far as possible with the down-cut milling method, can ensure that the cutting edge is smoothly cut away, the cutting brow bonded contact area is small, and in the role of high-speed centrifugal force is easy to be used up, to avoid the cutter teeth re-cutting into the workpiece due to chip impact on the front surface of the tool to produce flaking and chipping phenomenon, improve the durability of the tool

CNC Grinding

The grinding force of stainless steel is large and the grinding temperature is high. Under the action of high temperature and high pressure, Scraps will adhere to the working surface of the grinding wheel and block the pore of the grinding wheel, making the cutter lose the cutting effect. The rubbing temperature can reach 1000-1500 degrees Celsius so that the workpiece surface is easy to burn, the depth can sometimes reach 0.01mm ~0.02mm. And because of the action of grinding heat, the workpiece is easy to deform, resulting in size and shape error

CNC Machined Stainless Steel Applications

Many industries, including medicine, robotics, and aerospace, rely on CNC machining of stainless steel to create high-strength parts. This strong material can be used in applications like food packaging that require reliable durability or machinery operating in extreme temperatures. In short, it’s the ideal solution for any situation where reliability matters most!

标题文字1

标题文字2

标题文字3

标题文字4

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss.Gu

Phone: 18090076983

E-mail: kate@khled.com

Whatsapp:8618090076983

Add: Guangdong Province, China TianHe District, GuangZhou Num 899